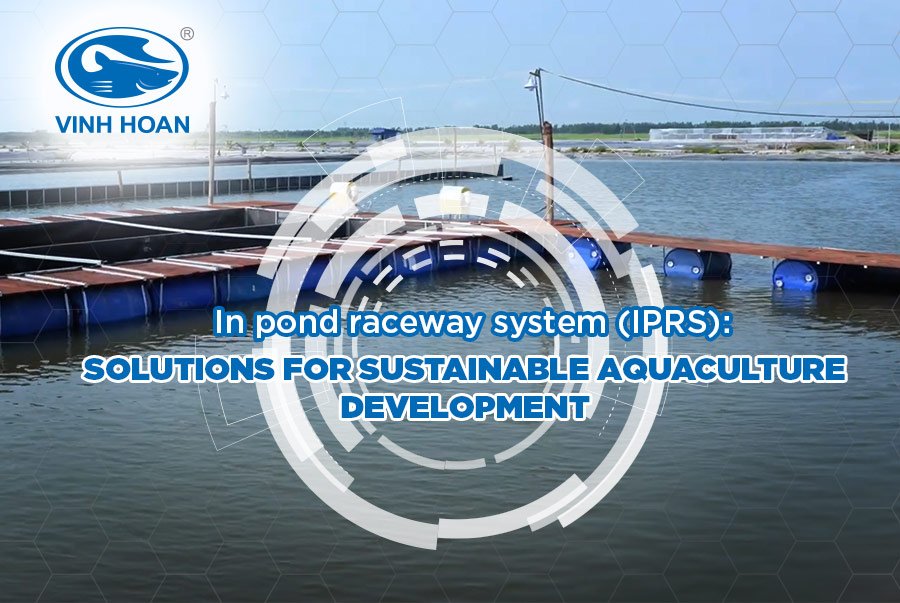

In Pond Raceway System (IPRS) Project

16 September 2021

In Pond Raceway System (IPRS)

Solutions to aquaculture practices innovations to conserve water resources and maximizing productivity

-

Aquaculture and water resources:

Up to now, our aquaculture practices have ensured sustainability criteria are recognized by international organizations. Thanks to that, our fish fillet products are accepted and loved by international markets with high standards such as the US, Europe, Japan, Australia… Besides meeting the growing supply-demand, there are also environmental challenges because natural resources are finite. How do we help farmers to raise more pangasius while preserving water resources, for future food production? After research, Vinh Aquaculture, a division of Vinh Hoan, collaborated with USSEC to implement The In Pond Raceway System (IPRS). This model brings not only economic efficiency but also an environmentally sustainable solution and resources.

-

How IPRS works:

The in-pond raceway system is a pond production technology originally developed at Auburn University and Clemson University back in the 90s and early 2000s. However, the use of floating troughs for lakes with water depths over 3m, is USSEC’s first trial in Southeast Asia.

The trough system actively feeds on-site water, regardless of the additional water supply. The water in the pond does not need to be replaced and can be used continuously for many years. Partitions are installed in the middle of the pond to ensure the circulation of the circulating flow thanks to white water systems in fixed areas outside the pond and a system of turning pipes. Water taken from outside the pond is aerated to increase dissolved oxygen and create water flow in the trough. The water stream has a high dissolved oxygen content to help fish breathe well; At the same time, it also has the effect of rolling the fish’s solid waste to the end of the trough.

At the end of the trough, the fish’s solid waste will be sucked away daily. The water after passing through the fish trough is drained out of the pond. The pond’s foreign environment has no fish or only a small number of filter-feeding fish. This is the place to treat the wastewater from the trough system before the water is pushed back to the fish trough. Farmed fish are fed by automatic machines, the portions are divided to feed throughout the day.

-

Outstanding advantages of The In Pond Raceway System (IPRS)

-

Increase productivity, increase the quality of fish

Thanks to the compressor system installed at the bottom of the pond, toxic gas will be released continuously. At the same time, the compressed air to the bottom of the tank also creates a flow that helps push the waste to one side, thereby increasing the dissolved oxygen content in the water. This process recreates the fish’s natural environment, thereby producing an environment more in line with the fish’s physiological sweet spot.

This helps farmers to raise fish at high density, raising many crops in a year, so the productivity and output are also 2-3 times higher than the conditions in normal ponds. After harvesting, farmers can release new seeds immediately without waiting for pond bottom treatment as before. This saves effort, time, and increases the number of crops.

-

Sustainable solutions for water resources

When applying IPRS, leftovers, and waste are sucked out. Thanks to this system, the water environment is always guaranteed, fish’s resistance is increased and disease is reduced.

In addition, instead of having to change the water in the pond regularly as in the traditional way, the river system in the pond does not change the water and discharge the water to the outside, thus avoiding the spread of pathogens to other ponds and convenient. in the care, management, and harvesting. Combined with biological treatment ponds, wastewater is treated to settle the soil and recirculate clean water into the farming stage.

Vinh Hoan is conscious of the importance of water usage and the potential negative impact of water discharge and will refine our methods for monitoring and follow-up. This innovation is an important part of the efforts Vinh Hoan is making to ensure environmental sustainability, prevent pollution, and continually improve performance across aquaculture farming.